Grease Trap Maintenance in Farmington, NH for Food Service Businesses

January 9, 2017 11:37 am Leave your thoughtsDealing with the fallout of a wastewater system that has been soiled with fats, oils and grease is not only costly but also time-consuming, and could slow down the day-to-day operations of a business. In order to avoid this fate, here are a few guidelines for grease trap maintenance in Farmington, NH that your company should follow.

Training employees

It is important to take the time out to train all of the employees on the correct disposal practices, and make sure that everyone understands what is expected from them. By the time the training is completed, all employees should know where the proper receptacles are, and the locations of all of the instructions and data sheets that they are expected to remain compliant with.

Training sessions are also a good opportunity to point out to employees what could happen if there is any deviation from the program in place. In addition to clogged pipes and expensive repairs, there could be legal ramifications that come with fines and violations, which could affect the operation of the business and threaten everyone’s job security. The better understanding all of the employees have of the system and its importance, the easier it will be for them to adhere to the guidelines.

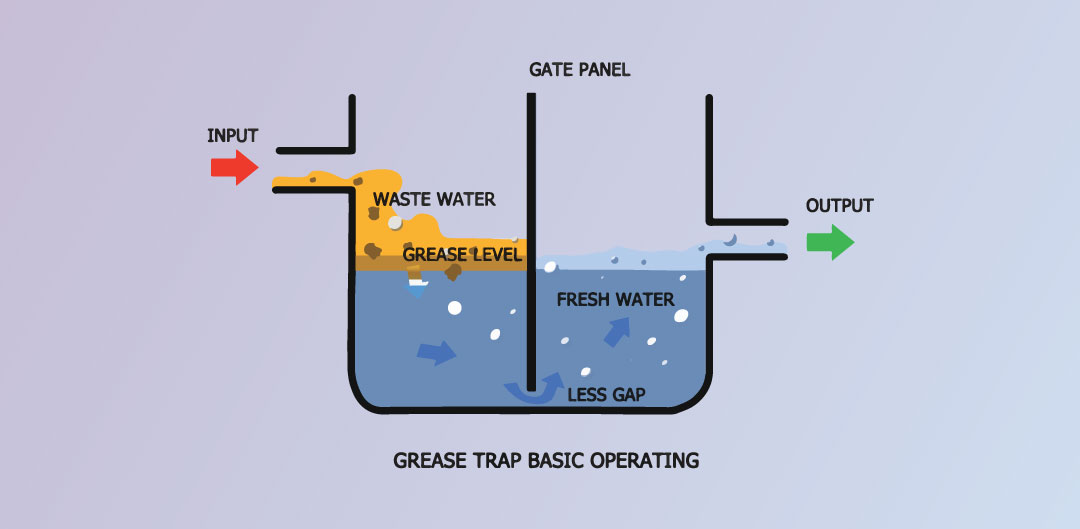

Reduce the grease

Disposing food waste in the proper receptacles is also a key factor in keeping the grease trap functioning at maximum efficiency. Large pieces of food take up valuable space and cause the grease trap to fill more quickly, which means that the trap would have to subsequently be maintained with higher frequency. In addition, post “no grease” signs in all washing areas and

grease discharge points to serve as daily reminders for everyone to continue to do their part.

It is also the manager’s responsibility to make sure that the grease traps are serviced and cleaned routinely, and to oversee this maintenance to make sure that everything is not only being completed properly, but also put back together correctly so as to avoid future issues due to reassembly mishaps. Every little bit helps, and with the entire staff working together to practice proper grease trap maintenance in Farmington, NH, you will extend the life of the trap and the septic system as a whole.

If you do run into any problems with your grease trap or septic system, or are just looking for further guidance on the correct procedures, be sure to call B.H. Cameron Septic Services LLC right away for an inspection.

Categorised in: Grease Trap Cleaning

This post was written by admin